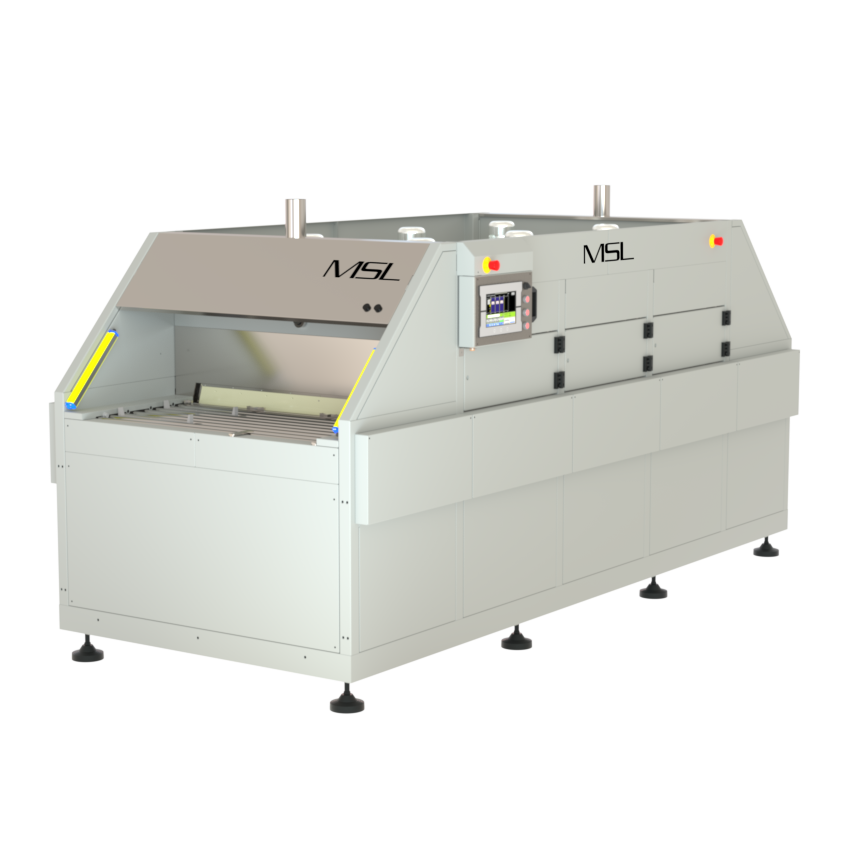

Conveyor Oven

Oven for continuous in-line treatments.

FULLY CUSTOMIZABLE

Conveyor Oven

Oven for continuous in-line treatments.

Clima & Thermotemperature range

From Ambient to 300° C

Characteristics

Hot

Capacity

Custom requirement

Options

Customizable according to your needs:

- Option to install a cooling zone with a refrigeration unit at the end of the oven.

- Programming of thermal cycles with I/O customizable according to customer requirements.

Characteristics

Equipment designed to use in production, both stand-alone and integrated into the production line, for a wide range of thermal treatments. The material to be processed is moved inside the oven with motorized rollers, while automatic doors ensure an airtight environment. Thanks to forced ventilation, precise temperature uniformity is guaranteed.

- Integration with other machines with SMEMA communication protocol (standard) or other proprietary protocols.

- Ability to perform the thermal cycle in an oxygen-deprived environment, achieved by constantly flowing nitrogen gas.

- Temperature control with digital PID electronic regulators.

- Remotable graphical interface on PC or mobile device.

- Flexible communication: Modbus TCP standard, with optional OPC UA and SQL.

- Secs-Gem Comunication to interface Host server with equipment HSMS comunication

- Remote assistance with Ethernet or mobile connection, using a smartphone connected with USB.

- Data and alarm management with a dedicated FTP server for log storage.

Clima & Thermotemperature range

From Ambient to 300° C

Characteristics

Hot

Capacity

Custom requirement

Options

Customizable according to your needs:

- Option to install a cooling zone with a refrigeration unit at the end of the oven.

- Programming of thermal cycles with I/O customizable according to customer requirements.

Characteristics

Equipment designed to use in production, both stand-alone and integrated into the production line, for a wide range of thermal treatments. The material to be processed is moved inside the oven with motorized rollers, while automatic doors ensure an airtight environment. Thanks to forced ventilation, precise temperature uniformity is guaranteed.

- Integration with other machines with SMEMA communication protocol (standard) or other proprietary protocols.

- Ability to perform the thermal cycle in an oxygen-deprived environment, achieved by constantly flowing nitrogen gas.

- Temperature control with digital PID electronic regulators.

- Remotable graphical interface on PC or mobile device.

- Flexible communication: Modbus TCP standard, with optional OPC UA and SQL.

- Secs-Gem Comunication to interface Host server with equipment HSMS comunication

- Remote assistance with Ethernet or mobile connection, using a smartphone connected with USB.

- Data and alarm management with a dedicated FTP server for log storage.