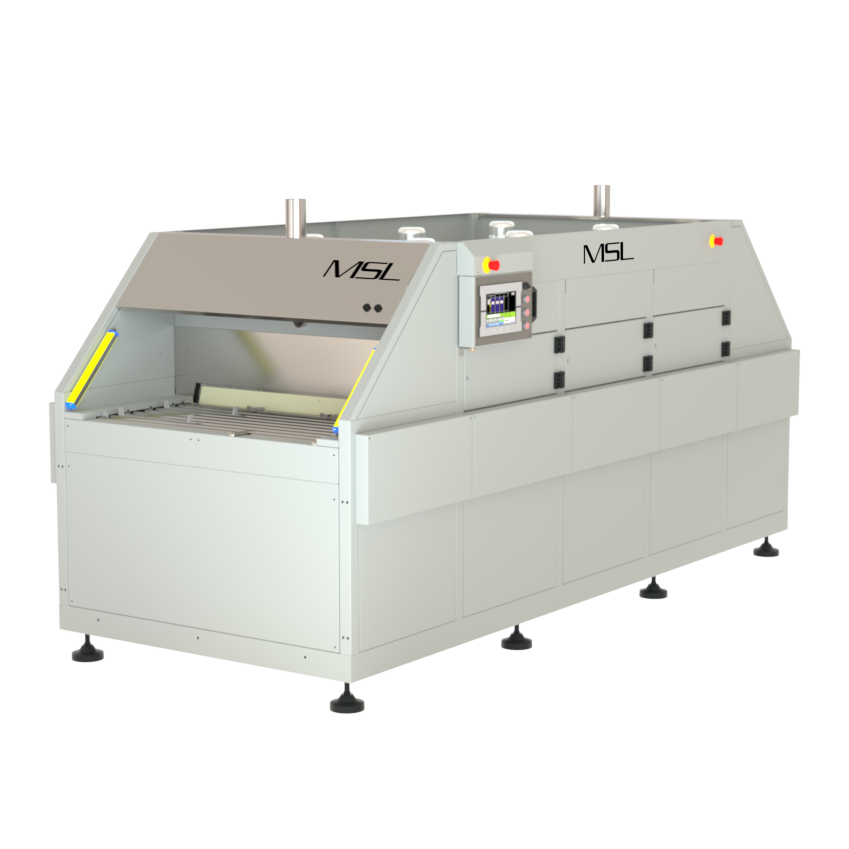

Line oven process

In our facility, we have embarked on an ambitious project: the construction of an oven for continuous cycle production, designed to revolutionize the way we support our customers in their manufacturing processes. This special machine is the result of careful planning and technological innovation, aimed at maximizing efficiency and ensuring high-quality results.

Phase 1: Design of the Compact Oven

Our journey begins with the design of a compact oven intended to optimize space without compromising performance. Its compact configuration allows for easy integration into various production lines, offering a versatile alternative for companies looking to enhance their production capacity.

Phase 2: Automation for Product Management

Once the structure is defined, we focus on automation for product management. This advanced technology enables precise, real-time control of materials throughout the entire process. Thanks to smart sensors and monitoring systems, it is possible to efficiently manage the production flow, minimizing the risk of errors and optimizing processing times.

Phase 3: Step Operation to Optimize the Cycle

The oven is equipped with a step operation system that allows for the optimization of the production cycle. This modular approach enables the oven to adapt to different production needs, ensuring maximum flexibility and performance. Each phase of the process is meticulously planned, ensuring consistent and high-quality results.

Phase 4: Inert Environment Process

One of the innovative aspects of our oven is its ability to operate in an inert environment. By using nitrogen and precisely controlling oxygen levels (ppm O₂), we can guarantee optimal conditions for material treatment. This not only improves the quality of the final product but also reduces the risk of oxidation, extending the lifespan of the treated materials.

Phase 5: Inspection Windows for Visual Monitoring

To ensure continuous control during the production process, we have integrated inspection windows into the oven design. These windows facilitate routine and extraordinary maintenance activities for operators. This feature enhances safety and allows for immediate intervention if necessary.

Conclusion: Towards New Opportunities

After months of design and development, our oven for continuous cycle production is finally ready for the market. Thanks to automation for product management, step operation, the inert environment process, and inspection windows, this machine represents a significant advancement in industrial production.

We are excited to see how this innovation can transform the production operations of our client companies, improving efficiency and the quality of the final product. This machine is more than just a tool; it is a symbol of our commitment to innovation and excellence in the industry.